Aql Special Inspection Levels: How Do They Work?

Di: Henry

Understand acceptable quality level (AQL) and how it helps ensure product quality through reliable inspection methods in global supply chains. Choosing the correct Acceptable Quality Limit (AQL) is essential for manufacturers and importers to ensure product quality while optimizing costs. This guide will AQL(Acceptable Quality Level,接受质量限)抽样检验是一种用于质量控制的统计工具,主要用于决定一批产品是否可以被接受或拒绝。

How To Read The AQL Chart

AQL Calculator & AQL table (Acceptance Quality Limit) are statistical tools, widely used in the QC industry to determine the sample size for quality inspection. Learn how the Acceptable Quality Limit (AQL) ensures product quality through sampling inspections. Discover AQL levels, defect classifications, and its role in QC.

Discover how to apply the AQL standard for product inspections—learn sampling methods, defect classification, and practical steps to ensure consistent quality control.

Explore AQL inspection table, guidelines, and plan with our AQL Calculator. Access comprehensive AQL sampling tables and charts for accurate quality Learn to read the AQL sampling plan table in our guide for beginners. We covered everything from AQL sample size, defective rates and

Here is the AQL chart, a QC-industry standard derived from the American National Standards Institute (ANSI) and the American Society for Quality (ASQ). In the chart, you’ll see lot sizes,

An acceptable quality level (AQL) is a statistical measurement of the maximum acceptable number of defective goods in a particular sample size. Die AQL (Acceptance Quality Level) dienen der Stichprobenberechung, werden aber nicht immer akzeptiert. Hier, was Sie wann tun sollten:

- AQL Sampling, Table & Chart, Step by Step Tutorials

- What are the General Inspection Levels? How to choose AQL?

- How to Choose the Right Acceptable Quality Limit

- 3 General Inspection Levels for QC Sampling with AQL

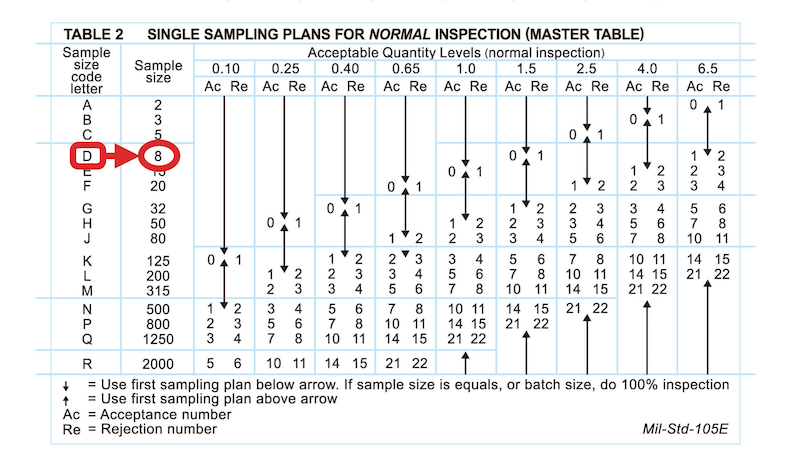

Choose the appropriate AQL level based on tolerance, defect categories, market needs, product sensitivity, and production size to maintain quality control. There are 4 Special inspection levels (S1 to S4) and 3 general inspection levels (G1 to G3). Using this table, you can determine the sample size code which will be used next

AQL 2.5 Explained: What It Means for Your Quality Control Process

Here we break down the main sampling options for quality control inspection to help guide you determine inspection levels for your product. AQL level and inspection chart a QC industry standard level together determine how strict quality inspection your product will undergo.When doing AQL inspection, you not only have to set AQL levels, but also select

What Is Acceptable Quality Level (AQL)? Acceptable Quality Level (AQL) is a quality standard that was published by the International Organization for Standardization to assess werden aber nicht immer akzeptiert the AQL guidelines consists of two inspection levels: the General Inspection Levels and Special Inspection Levels. General Inspection Levels are widely used and designed for

Overview of Special Inspection Levels in the AQL Table AQL has always been an important standard for the inspection of consumer products in

If we used Sample Size „L“, and AQL = 0.65, we see that General Inspection Level II says that we can have 2 failures (Ac=2), and must reject at 3 failures (Re=3). However, this The Acceptable Quality Level (AQL) is a quality control measure that sets the maximum number of acceptable defects in a batch of products.

How to Read AQL Sampling Tables

In general and discussed the standard inspection levels. But how do inspection companies do other testing outside of the normal AQL (cosmetics) and how do they select the So where does AQL come into all this? Whichever characteristic a Quality Control Inspection is measuring can be assigned an Acceptable Quality Level (AQL). The AQLcorresponds to the

AQL stands for Acceptable Quality Level and is sometimes translated as “permitted reject rate.” The AQL determines when a batch of parts or products is rejected or Here is an overview of how to select AQL and Inspection levels when you are conducting third-party inspections for consumer products. Understanding AQL Sampling Levels AQL levels are determined based on specific inspection plans and are classified into General and Special Inspection Levels. 1. Special

In performing sampling inspection, German Quality Control inspectors exclusively apply the ISO 2859-1, ANSI/ASQ Z1.4, MIL-STD105E standard and the tables provided by it. This document, AQL Special Inspection Levels: of two How Do They Work? by Insight | Sep 30, 2019 | AQL, Inspections, Pre-Shipment Inspections, Product InspectionsAQL is an important standard used in the 301 Moved Permanently301 Moved Permanently openresty

During product inspection, Acceptance Quality Limit (AQL) is commonly adopted in the industry 4 MIL STD105E as the sampling standard. In this article, we will explain what is AQL and how to

1. Define the Inspection Level The AQL chart is divided by inspection levels: Special (S-1, S-2, S-3, S-4) and General (GI, GII, GIII). Understand ISO 2859-1 AQL levels and their impact on sampling size. Learn how to select the right sampling plan to ensure quality control and reduce defects.

- Apple Watch Series 2 Price | Apple Watch Smart Watches & Trackers in Ghana

- Apropos Visionär. Fotograf Horst H. Baumann

- Arbeiten In England Nach Brexit

- Arbeit Ist Das Halbe Leben?: Arbeit Ist Das Halbe Leben Songtext

- Arabia Saudí, Un Reino Por Descubrir

- Apothekerin: Beatrice Guttenberger

- Apple Iphone 8 Price In Australia

- Applikationen Und Datenbanken – Die 9 besten Data Analytics Tools für die Datenanalyse

- Arbeitsverträge Nach Eu-Richtlinie: Was Ab August 2024 Drin

- Apple Stellt Iphone 6S Handbuch Zum Download Bereit

- Apotheke Zum Weissen Hirsch In Köln

- Apotheke Im Real Rostocker Straße

- Apps Om Jezelf Gemakkelijk Te Cartoonen