Basics Of Injection Molding Design

Di: Henry

Injection Molding Guide Nowadays to remain competitive, the need to constantly improve injection molding processes can benefit from modern technological advancements that simulation ofers to overcome known disadvantages. With the aid of sophisticated computer-based tools, virtual product design enables engineers to look at and gain a better understanding of the entire The injection mold, a key element that defines the quality, efficacy, and cost-effectiveness of the finished product, is at the center of this process. Engineers, designers, and producers who produce plastic parts need to understand injection mold design basics

MOULD DESIGNING COURSE in INDIA

Explore our latest guide as we explore the basics of injection moulding processes, including: how it works, design principles, materials, and more. Preface During the last fifty years I have been almost continuously working with molders, mold makers and mold designers, and in doing so learning the intricacies of designing of molds for many different products, from the early, simple compression molds to highly sophisticated injection molds.

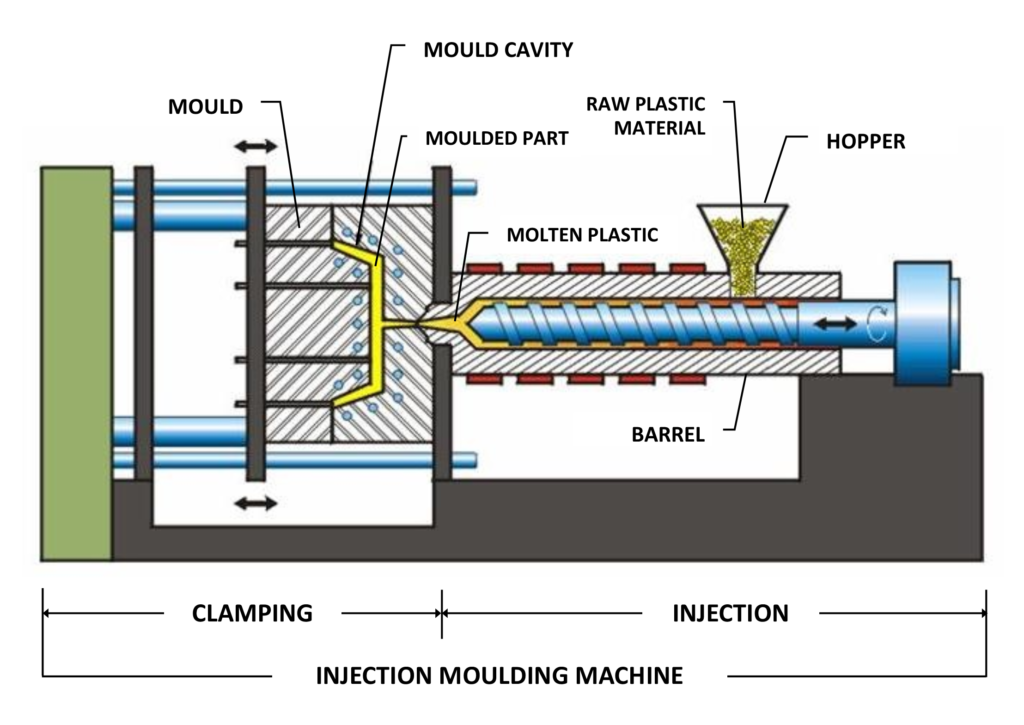

Injection molding is a widely used manufacturing process for producing plastic parts and products. It involves the injection of molten material into a mold cavity, where it solidifies to form the desired shape. This comprehensive guide covers various aspects of injection molding, from its history and core concepts to mold design, process optimization, applications, quality

Learning correct mold design for the plastic injection molding process molding process involves melting is critical to project success. This guide covers everything you need.

This document provides an overview and summary of the book „Fundamentals of Plastics Mould Design“. The book covers fundamentals of product design, injection mould design, compression mould design, transfer mould design,

Learn the processes, requirements, and limitations of injection molding, the go-to manufacturing process for large-volume plastic part production. What is plastic injection molding? Plastic injection molding is the most commonly used manufacturing process for the production of small, medium, and large-sized plastic parts. The process utilizes an injection molding machine, raw plastic material, and a mold. The plastic is melted to molten heat in the machine and then injected into the mold, where it cools and

Basic of Mould Design – Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses the basic stages of injection moulding including feeding plastic into Fundamentals of Mould Design – Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses factors to consider when designing molds for plastic products and injection molding. It covers: 1. Properties of the plastic material, function of the product, and manufacturing method should be considered Learn about the basics of injection molding design to save time and money while ensuring the manufacturability of your parts.

Demystify how injection moulding works. This guide covers the complete, step-by-step process, including DFM, materials, tooling, and modern applications. This document provides an overview of injection an overview of injection mold molding design. It discusses factors to consider like part usage, loads, and processing issues. Adhering to basic design rules can result in stronger, easier to manufacture parts. The

The design of the main components of an injection mold will be discussed and good design practices, rules of thumb, and key calculations will be shared. More than 600 fig-ures, images and tables are provided in the book to illustrate how a mold should be designed.

The document discusses the key considerations in injection mold design, including the feeding, cooling, and ejection systems. It covers different types of molds and runner systems, as well as important phases like parting lines, weld lines, sinks, and undercuts. Simulation tools can be used to analyze factors like fill time, fiber orientation, warpage, and cooling design. Proper gate This document provides an overview of various plastic molding processes and their applications. It discusses the main molding types including injection molding, blow molding, compression molding, vacuum forming, rotational molding, and extrusion molding. Injection molding is commonly used in automotive applications due to its ability to produce complex parts with Injection molding is a common manufacturing process used to produce plastic parts at scale. Properly designing parts for injection molding is critical for avoiding defects, controlling costs, and achieving the desired appearance and performance. This comprehensive design guide outlines key considerations across part geometry, material selection, tooling, and

Master the basics of injection molding design with our comprehensive guide. Learn key principles for successful manufacturing.

- Your Ultimate Injection Mold Design Tutorial

- How to Design for Injection Molding

- Fundamentals of Injection Mold Design

- Plastic Injection Mold Making

The document discusses the basics of injection molding design. It states that injection molding design involves considering both functional requirements and processing factors like how the molten plastic fills the mold cavity. Following

The molds used in injection molding can be expensive to design and fabricate, especially for complex parts with intricate features. Additionally, the setup and maintenance of injection molding machines can be time-consuming and require skilled operators to ensure proper operation and consistent production.

The injection molding process involves melting plastic and injecting it into a mold cavity where it cools and hardens into the final shape. Adhering to design principles like minimizing stress concentrations can result in stronger, easier to manufacture parts.

The injection mold design tutorial is the best guide there is for the money. Gates, runners, shrink, CAD design, mold flow analysis, parting lines and more. RSTOOLS ACADEMY is providing basic to advance Industry level Injection Mould Design Course. Mold Making is a must thing to do before starting Mould Designing Course because we do the mould designing for machineries and without knowing the limitations and features production of small medium of all machines it’s hard to learn mould designing & Industrial Experience is The Basics of Injection Molding Injection molding was first developed in the 1930s and has since become one of the most popular manufacturing processes in the world. It is used to produce a wide variety of products, from consumer goods to industrial components, and is particularly well-suited for high-volume production runs.

The final phase was manufacturing and assembling of the parts of the mould. Manufacturing of the mould was strictly done as per the drawing specifications and the mould trial was carried out on the injection moulding machine. The final product produced was found to meet all the specifications as per the customer requirements. The study of design variations in the mould

In this video, we will understand the basic working of the injection molding process, learning about the mold cycle, thermoplastics and thermosets, and plastic processing methods. Learn how to design for injection molding. This guide provides an overview of injection mold design considerations and potential defects caused by poor design.

INJECTION MOULD DESIGN Published by Dr.SSureshKumar, 2017-09-14 22:43:37 Description: INJECTION MOULD DESIGN BY R W G Pye Injection molding is a widely used manufacturing process to advance Industry level Injection for producing plastic parts by injecting molten material into a mold. Designing parts for injection molding requires careful consideration of various factors to ensure

In the first few sections of the basics of mold design, we will mainly look at the theory behind mold design. In the subsequent sessions, you will be capable of designing the mold using SolidWorks. Here is the table of contents for this part down below: What is injection molding? Mold cycle Thermoplastic and thermosets What Is Injection Molding? Injection

This guide has all you need to know about Injection molding and how to get start-ed with the mass-production of plastic parts. Master the basic principles of the technology and learn quickly actionable design tips that save time & cut costs. Table of Contents Learn the key steps in plastic injection mold design, from parting line selection and draft angles to wall thickness, radii, and cooling channels. Injection molding is a highly developed industrial manufacturing process widely used for mass production of plastic components. For engineers, understanding the molding process, material characteristics, mold design, processing parameters, and applications across industries is key to improving product quality, shortening development cycles, and controlling

Plastic injection molding refers to the injection of molten plastic at high pressure into a pre-designed template known as a mold. The molten plastic is then allowed to cool to form an object in the shape of the mold. This process is used to design a variety of utensils, packaging, toys, and many other objects. As a product manufacturer, plastic injection summary of the book molding may be of great Design plays a critical role in injection molding as it directly influences the quality, functionality, and manufacturability of the final product. By carefully considering design aspects, manufacturers can optimize the injection molding process, ensuring the production of high-quality parts that meet the desired specifications.

This document discusses the basics of injection molding design. It covers key topics like the injection molding process, common polymers used, equipment involved, and design considerations like gates, wall thickness, and defects. The injection molding process involves melting plastic and injecting it into a mold cavity to form parts. Adhering to plastic into Fundamentals of basic design rules This study centers on the design and construction of an injection mold specifically for the bottom cover of an automobile air filter box assembly. The biomedical application of CAE in the design process enhances precision, efficiency, and the production of high-quality parts in the injection molding of technical components.

- Bar Globus Artemide Ø 50 Cm _ Zoffoli #88, globus med barskab, globusbar, 50 cm

- Batch Datei Leerzeile Hinzufügen

- Bauernhaus Oder Landhaus In Kreis Fulda Mieten Oder Kaufen

- Batterien Online Günstig Kaufen Schweiz

- Bauer Sucht Frau 2014: Biobauer Gottfried Startet In Die Hofwoche

- Basically Steel Ball Run , An open world Steel Ball Run game would be cool for PS4

- Bastelanleitung Für Ein Origami-Einhorn

- Battle Of Ia Drang, 1965 _ Ia Drang Valley: where the US truly went to war

- Barack Obama Inaugural Address: Jan. 20, 2009

- Barcelona Souvenirs: 10 Things To Buy

- Bauer Sucht Frau-Star Anna Heisers Baby Ist Da

- Barbie – Barbie Official Website

- Bat Droppings And Urine – What Are The Top 10 Signs You Might Have A Bats In Your Attic