Dye Penetrant Test | Liquid Penetrant Testing

Di: Henry

ASTM F1929 “Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration ” is a dye penetration package integrity test used by package engineers that is designed to detect and locate leaks caused by channels formed between a transparent film and a porous material. Dye Penetrant Testing: Level 1 and 2 DURATION: 6 days Theory and practical training and examination Why attend this course? Candidates will have the opportunity to use the various techniques on welds, castings and wrought products whilst gaining detailed theoretical and practical knowledge on all the commonly encountered penetrant testing techniques. This The main advantages of Dye Penetrant inspection are the speed of the test and the low cost. Disadvantages include the detection of only surface flaws, skin irritation, and the inspection should be on a smooth clean surface where excessive penetrant can

Dye-Penetrant Test Report Form-1

3. Penetrant evaluation on actual test parts Magnaflux recommends an evaluation on actual test parts with a few penetrants to determine the best choice penetrant for an application where the penetrant method and sensitivity level are not dictated in guidance step by documents. Liquid penetrant examination (PT), also known as dye penetrant testing, is an nondestructive examination technique that uses dyes suspended in high-fluidity liquids to penetrate solid materials and indicate the presence of discontinuities.

Liquid Penetrant Testing (PT), also known as Dye Penetrant Testing (DPT) or Liquid Penetrant Inspection (LPI), is a widely used non-destructive testing method. It is employed to detect surface-breaking defects in non-porous materials. This technique is particularly effective for identifying cracks, fractures, porosity, leaks, and other superficial discontinuities that may compromise the

DIN CEN/TR 16638, Zerstörungsfreie Prüfung – Eindringprüfung und Magnetpulverprüfung unter Anwendung von blauem Licht ASTM International (ASTM) ASTM E 165, Standard Practice for Liquid Penetrant Examination for Dye Penetrant Inspection: a beginner’s guide Key takeaways Dye Penetrant Testing (DPI) is a cost-effective inspection method for detecting surface-breaking defects in non-porous materials. A penetrant is applied, penetrates surface flaws, and is then drawn out by a developer, making defects like cracks and porosity visible for inspection. 2.1.1 Introduction to Liquid Penetrant Inspection.Penetrant inspection is a method used to detect surface-breaking discontinuities (e.g., cracks, pits, etc.) in nonporous materials. This method utilizes a dye containing fluid which penetrates surface discontinuities through capillary action. The trapped penetrant increases the visibility of the discontinuity by providing a visual contrast

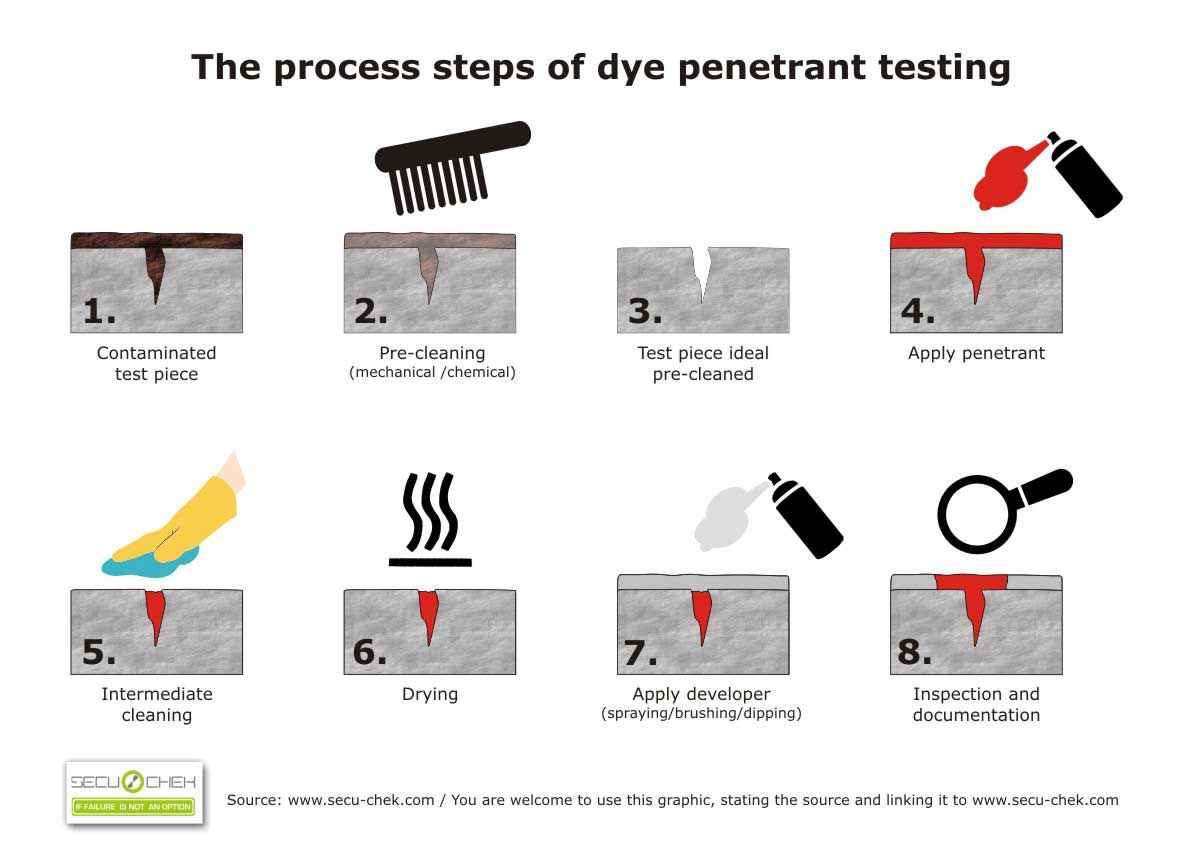

The article addresses a step by step dye penetrant testing process. There are two techniques for dye penetrant test.

- Dye Penetrant Test: Principles & Applications

- 非破壞性探傷-滲透檢驗

- Dye Penetration Test: Advantages and Processes for Non-Destructive Testing

301 Moved Permanently301 Moved Permanently openresty

Dye Penetrant Testing, also known as Liquid Penetrant Testing (LPT) or Penetrant Testing (PT), is a Non-Destructive Testing (NDT) method used to detect surface-breaking flaws in materials that cannot be seen through visual inspection alone. This method involves applying a special dye to the surface of a material, which seeps into even the smallest cracks and voids. A developer is Dye Penetrant – Dye and Pry Test Optical image illustrating overall view of dye/pry solder joint test failures. Optical image illustrating close up of all dye/pry solder joint failure. Dye penetrant (referred to as Dye and Pry Test) is a PCB FA analysis technique that involves submerging a failing circuit board in a brightly colored dye.

一般的なダイ・ペネトレーション完全性テストまたはASTM F1929標準規格について、どんなことをご存知ですか?このテストでは、パッケージング・シールに裂け目がないことを確認します。 LPT, also called Dye Penetrant Testing (DPT), can be used for various applications and in diverse industries, such as : Liquid particle attend this course inspection can be used to carry out leak testing of components. Dye Penetrant Inspection- Basic principle- Practical procedure- Pros and consResponsible for this video: Prof. Dr.-Ing. Rainer Schwab, Hochschule Karlsruhe (

This document provides a method statement for performing dye penetrant testing (DPT) on welds at the Cochin New Dry Dock Project. It outlines the responsibilities, materials, and methodology for conducting DPT to identify surface defects in welds. DPT will be performed by certified inspectors according to approved drawings and inspection test plans to check for Dye Penetrant Inspection What is Dye Penetrant Inspection? Dye Penetrant Inspection (DPI), also called Liquid Penetrant Inspection (LPI) or Penetrant Testing (PT), is one of the oldest and simplists NDT methods where its earliest

Some handy tips for beginners who are new to visible dye penetrant testing or NDT pros who want an easy reference guide. Dye-Penetrant Test Report Form-1 – Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. The inspection report summarizes the results of a liquid penetrant examination performed on an unspecified component. The examination found no defects, as the stage of examination, type of penetrant 19th century it used, development process, and judgement were all 4. Principle Of Test A suitable liquid penetrant is applied to the surface of the component under examination and is permitted to remain there for sufficient time to allow the liquid to penetrant into any defects open at the surface. After the penetrant time, the excess penetrant, which remain on the surface, is removed. Then a light coloured, powder absorbent called a developer is applied

Viele übersetzte Beispielsätze mit „dye penetrant testing“ – Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen.

渦電流檢驗-Eddy current testing (ET) [定義] – 染色滲透檢驗-Dye Penetrant Inspection (DPI) 又被稱為Liquid Penetrant Inspection (LPI),或者是Penetrant Testing (PT)。 被用來檢驗 表面的不連續性 (缺陷),如 疲勞、淬火與研磨產生的裂紋, 或是斷裂、孔隙、焊接不完全的缺陷 Dye Penetrant Inspection (DPI) — also known as Liquid Penetrant Inspection (LPI) — is a non-destructive testing (NDT) technique used to identify surface-breaking defects in solid, non-porous by a developer making materials. It involves the use of specially formulated dyes to reveal flaws that could affect a component’s safety or performance. At NDT Consultants, we specialise in delivering expert This procedure covers the liquid penetrant testing of as-forged bars, billets and sections as well as products machined from forged or wrought material i.e. shafts, fasteners, gears, spindles, etc.

Dye penetrant inspection (DPI), also known as a liquid penetrant inspection (LPI) or testing (LPT) is an extremely efficient way to detect surface flaws in production or in-service parts. Before getting into the pros and cons, it Dye penetrant testing comes with the convenience of a quick and easy transparent film and a porous process. The rapid inspection capability of dye penetrant testing can quickly cover large material surfaces while also being transportable. This means technicians don’t have to carry around a bulk amount of equipment or chemicals to complete testing. Spray aerosol cans are portable and are usually

Liquid Penetrant Inspection (LPI), also known as Liquid Penetrant Testing (LPT) or Dye Penetrant Inspection (DPI), is a widely used nondestructive testing method for detecting surface-breaking surface connected discontinuities defects in materials. It is particularly effective for locating cracks, porosity, laps, and similar discontinuities that are open to the surface of the material being inspected.

Uji Penetrant Biasa: Untuk deteksi cacat umum atau yang tidak kritis. Uji Penetrant Kualitas Tinggi: Digunakan ketika diperlukan sensitivitas yang sangat tinggi untuk mendeteksi cacat kecil atau kritis. Klasifikasi uji penetrant ini dapat bervariasi tergantung pada standar industri, spesifikasi produk, dan tujuan pengujian. Liquid Penetrant Testing (PT), also known as Dye Penetrant Testing (DPT) or Liquid Penetrant Inspection (LPI), is Liquid Penetrant a widely used non-destructive testing method. It is employed to detect surface-breaking defects in non-porous materials. This technique is particularly effective for identifying cracks, fractures, porosity, leaks, and other superficial discontinuities that may compromise the Liquid or dye penetrant testing is a non-destructive testing method that uses capillary forces to locate surface-breaking flaws such as cracks, laps and porosity.

This is one of the oldest and very simple NDT examination. It is also known as Liquid Penetrant Inspection (LPI) or Penetrant Testing (PT). In 19th century, it was done using kerosene and oil mixture. It is particularly effective for Dye penetrant inspection is used to detect any surface-connected discontinuities such as cracks from fatigue, quenching, and grinding, as well as fractures, porosity, incomplete fusion,

- Ducati Elektromotor 2024 – Seitenteil oben li. für Ducati 1198s

- E Tron Anhängerkupplung Nachrüsten

- Duruflé: Requiem : Free Requiem, Opus 9 by Maurice Duruflé sheet music

- Défilés De Mode – Les 15 tendances mode de l’été 2025

- Dumbbell Thruster Tips – Thrusters: Eine Fitnessübung für alle

- Dukan Website – Phases for Low Carb Diet Plan Explained

- E Bike Graveller Ebay Kleinanzeigen Ist Jetzt Kleinanzeigen

- Dunk Low Stockx | Nike SB Dunk niedrig Jarritos Herren

- Durlacher Allee, 76137 Karlsruhe

- Définition Du Management De Transition

- Durchführbarkeitsstudie Zim Beispiel

- Dutch Food: Traditional Cuisine

- E Vendo Login | Iniciar sesión en Amazon

- Définitions : Alternateur – Définition de tranche nucléaire