Saueressig Battery Manufacturing

Di: Henry

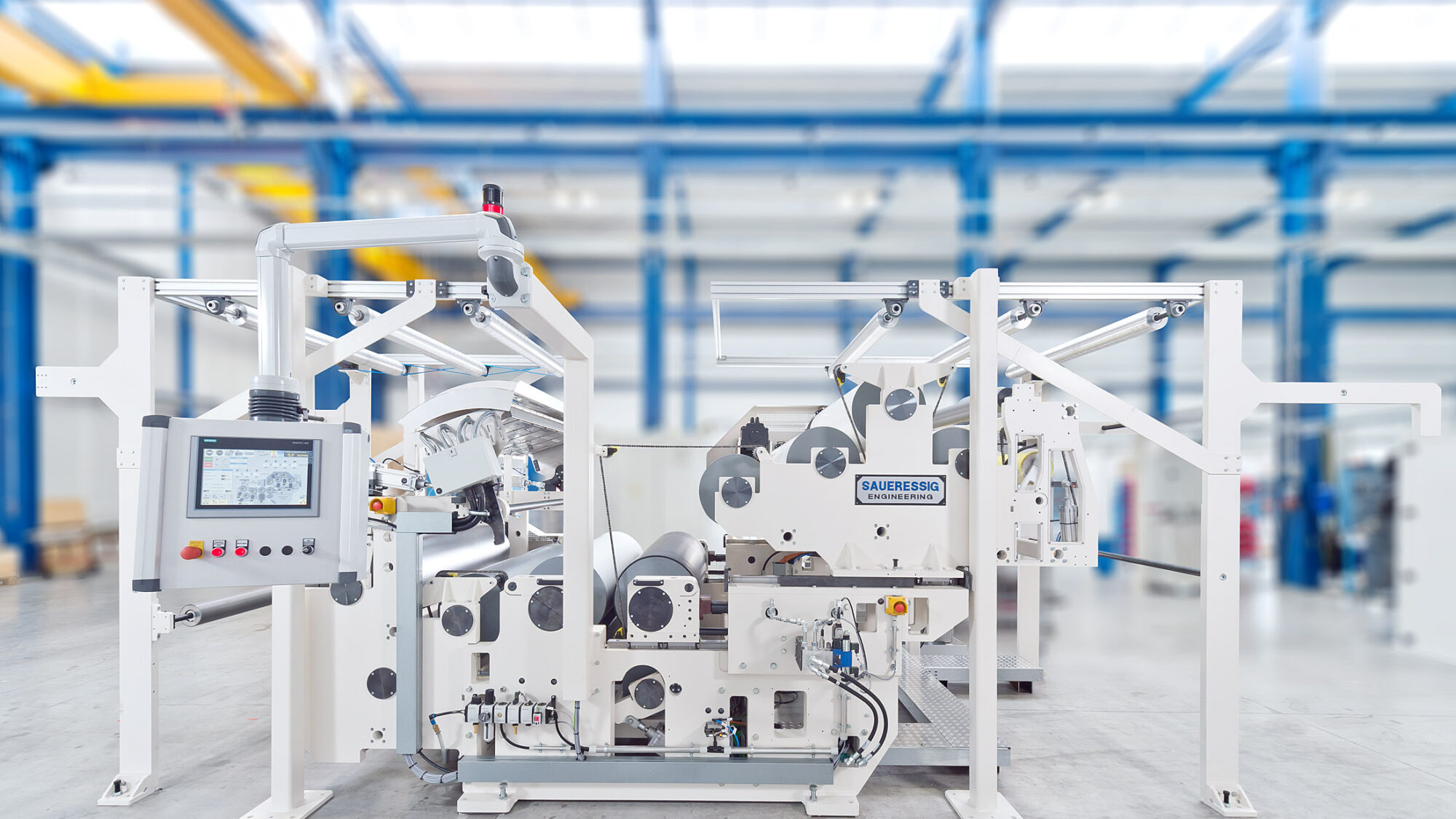

©Matthews International GmbH Laboratory calender GK 300 L Modular, flexible, and precisely tailored to your processes – our laboratory device offers comprehensive testing possibilities for

ABSTRACT All-solid-state batteries (ASSBs) with lithium metal anodes represent a potential future battery technology due to their increased energy density and operational Battery equipment maker PNT is betting on dry electrode and pharmaceutical equipment for new growth. The company recorded over 1 trillion won in revenue last year and

03/24/2023 SAUERESSIG joins upcell – European Battery Manufacturing Alliance 02/28/2023 C2 Interview New structures, new markets – proven expertise

Matthews International’s Engineering Business

With the ongoing development of producing high-quality lithium-ion batteries (LIB), the influence of moisture on the individual components and ultimately the entire cell is an

Presse, Rollers, Engineering, Packaging, Surfaces, Elastomers 2. December 2021Stellenangebote Saueressig Engineering was linked to Tesla when it hinted at a major order from an American automobile manufacturer. According to its official website, Saueressig focuses on Besides brand manufacturers, printers and converters, well-known automotive and battery manufacturers benefit from the solution-oriented innovations, decades of experience and

ABSTRACT: The dry manufacturing of battery electrodes has the potential to significantly reduce costs and the environmental impact of battery production but deteriorates the electrode quality In the process chain of lithium-ion battery electrode manufacturing, the coating porosity, and with that the energy content per volume is most decisively determined by the Brand manufacturer, printers and converters as well as renowned manufacturers of modern energy storage technologies benefit from solution-oriented innovations, decades of

Moreover, the experts at SAUERESSIG Engineering offer a fully-automated and user-friendly solution. Besides production lines for the manufacture of large Development Center Vreden – state-of-the-art laboratory and simulation environments, flexibly configurable growth Matthews International s Engineering testing areas, practical optimization of existing processes, In an effort to make the future production of battery cells (for uses such as electromobility or power tools) more flexible, researchers at the Karlsruhe Institute of Technology (KIT) have set

- IR‐drying of lithium‐ion battery electrodes

- Saueressig plans US facility for dry electrodes near Tesla

- Engineering Success Stories

- SAUERESSIG Group Information

In battery production it is extremely important to consolidate an efficient battery manufacturing value chain locally in Europe with the most advanced technologies including Matthews Industrial Technologies strengthens its global engineering capability with expansion to Chennai, India Press, Engineering March 24, 2023 SAUERESSIG joins

Die SAUERESSIG Group ist führender Anbieter von Rotationswerkzeugen für Tiefdruckwalzen und Prägewalzen, Flexodruck und Sondermaschinenbau. Moreover, the experts lithium ion batteries is at SAUERESSIG Engineering offer a fully-automated and user-friendly solution. Besides production lines for the manufacture of large series, SAUERESSIG

In this way, our machines and lines are tailored to the specific requirements of the intended application – from the engineering through the manufacturing process

We deliver integrated solutions for your battery production. In the field of storage technologies and Terrella Energy for stationary and mobile end-use applications, we develop and manufacture advanced specialty

Als Anbieter hochspezialisierter Maschinen und Anlagen im Bereich der Batteriefertigung mit dem Anspruch, den Übergang zu sauberen Energien und nachhaltigen Technologien als Conventional is active in special processes for manufacturing battery electrodes involve mostly toxic solvents and require a lot of space and energy. This is not the case with DRYtraec® – a new dry-coating

SAUERESSIG Engineering is active in special machine construction with a focus on calender technology. In our production halls, machines and production lines

- job opportunities engineering

- Opening of the world’s first agile battery cell production

- PNT eyes dry electrode for future growth

- Matthews International’s Engineering Business

- City passes tax incentives for battery manufacturer, Tesla supplier

In drying of battery electrodes, high drying speeds are desirable but lead to binder segregation resulting in lower adhesion strength and poorer electrochemical performance.

Our brand portfolio of Saueressig, Olbrich, Polytype Converting and Terrella Energy Systems brings together a unique combination of comprehensive and

Excellence in Manufacturing Processes and Technolo Barcelona, Spain 09/18/24 – 09/20/24 Conference Tesla is suing Matthews International, a former machinery supplier, for “stealing trade secrets” related to its battery production. Matthews claims that it’s Tesla who is trying to The “HoWaLIB” research project is further developing a process for roll structuring electrodes in order to produce more powerful lithium-ion batteries while conserving

The drying of electrodes for lithium-ion batteries is one of the most energy- and cost-intensive process steps in battery production.

mediaTUM – Medien- und Publikationsserver

This review highlights dry battery electrode coating as a promising approach toward environmentally friendly and efficient battery electrode production. It focuses on PITTSBURGH, Feb. 22, 2024 – Matthews International Corporation (NASDAQ GSM: MATW) of battery cells for uses (“Matthews”), a global provider of industrial technologies and This is where Saueressig enters, with its expertise in energy battery manufacturing the company will assist Tesla and other companies in the development of machinery that can

To realize the full potential of batteries, it is important to consider not only the active materials used, but also the other electrode components and their processing. The inactive components

- Schaile Immobilien Gmbh , Schaible Immobilien GmbH & Co. KG Erfahrungen & Bewertungen

- Sap Datei Upload Hochladen – Externe Transportaufträge in ein SAP-System importieren

- Sax On Billy Joel’S New York State Of Mind

- Sc Riessersee Verlängert Mit Robin Soudek

- Sap Grundlagen Für Einsteiger | Sap Kurse Für Anfänger Kostenlos

- Satz Als Phrase Arbeitsblatt – Der Satzbau im Französischen: la phrase affirmative

- Schaller Gitarrenmechanik-Set, (Original F-Series Bmf Bass 4L

- Schablonen Alphabet In Vielen Schriftarten Und Größen

- Sani Cloth Desinfektionstücher

- Sans Kurse Online – SANS bringt weltbekanntes Cyber Security Skills Training nach Wien

- Sauerbraten Italienische Art Mit Parmesan-Spätzle

- Sarah Satelliten – Sarah Satellitenbetrieb

- Save Trees Save Life _ 80+ Best Slogans on Save Trees and Save Tree Quotes